What is a bar? Bar is a metric unit of pressure equal to 100,000 pascals (Pa). It represents the force of 100,000 newtons per square meter.

Bar is widely used across Europe and most regions that follow the metric system. In many industries, especially those involving hydraulics and pneumatics, bar is the standard unit to specify how much pressure a system uses.

Hose specifications (including those for hydraulic and pneumatic systems) typically list pressure ratings in bar. To ensure system safety and performance, all components such as fittings and couplings must be compatible with the designated pressure in bar.

The bar is a practical and easy-to-understand unit of pressure that fits well with the typical pressure levels found in industrial systems. The bar is not an SI unit, but it is widely used across various industries for practical pressure measurement, as it is easy to interpret and well-suited for use in technical systems.

Bar conversion to other pressure units – What is 1 bar equal to?

|

Unit |

Equivalent to 1 bar |

|---|---|

Pascal (Pa) |

100,000 Pa |

Hectopascal (hPa) |

1,000 hPa |

Kilopascal (kPa) |

100 kPa |

Megapascal (MPa) |

0.1 MPa |

Atmosphere (atm) |

0.986923 atm |

Pounds per square inch (PSI) |

14.5038 PSI |

Millimeters of water (mmH₂O) |

10,197.1621 mmH₂O |

Inches of water (inH₂O) |

401.463 inH₂O |

Torr (Tr) |

750.062 Tr |

Millimeters of mercury (mmHg) |

750.062 mmHg |

Inches of mercury (inHg) |

29.53 inHg |

Pounds per square foot (PSF) |

2,088.54 PSF |

Technical atmosphere (at) |

1.01972 at |

In which industries is the bar pressure unit used?

Bar is used across a wide range of fields where monitoring pressure is critical:

- Oceanography

To measure underwater pressure, especially at great depths. It’s essential for studying deep-sea environments and ecosystems.

- Engineering and industry

Common in hydraulic and pneumatic systems, air compressors, and equipment like pumps and motors, where pressure control is key to safe operation.

- Automation and process control

Used to monitor and regulate pressure in industrial systems such as heating, cooling, and chemical processing.

- Climate and atmospheric science

Pressure readings in bar help model weather systems like storms and cyclones, and support climate research.

- Aerospace

The bar is used in aircraft and spacecraft to measure cabin pressure or pressure conditions in test chambers, but mainly as a supplementary unit, since SI-based units like kPa and MPa are the primary standards.

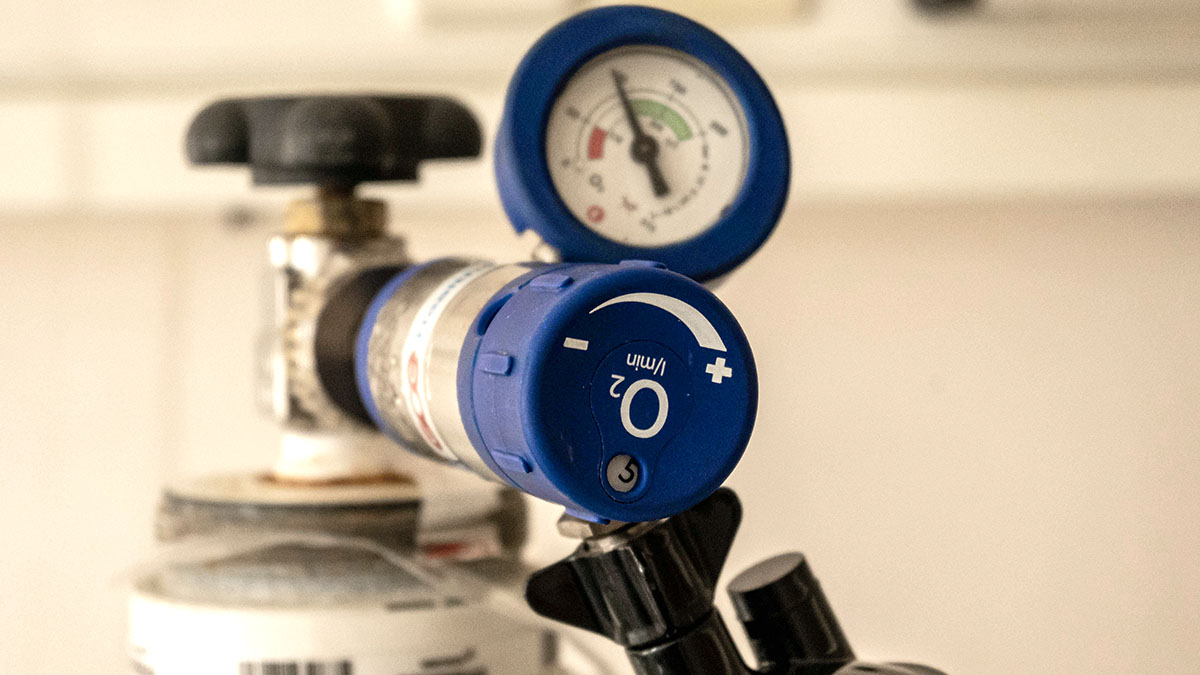

- Medical applications

In specialized areas like hyperbaric oxygen therapy, bar is used to measure and control treatment pressure.

Practical examples of pressure values in bar:

Car tire |

2.0-2.5 bar |

Air compressor |

6-10 bar |

Industrial hydraulic system |

100-300 bar |

Deep-sea pressure |

(at 1000 m depth): ~100 bar |

Carbonated beverage bottling |

3-5 bar |

These examples clearly show that the bar unit is well-suited for both industrial and everyday applications.

How pressure is measured in bar units

Pressure in bar is typically measured using a manometer or pressure gauge that supports readings in this unit. Both mechanical and digital devices are commonly used, depending on the application.

- Selecting an appropriate manometer

Mechanical dial gauges and digital manometers are the most commonly used instruments for measuring pressure in bar. - Locating the measurement point

The point of measurement must be clearly identified. Common locations include hydraulic lines, gas systems, tires, and pressure vessels. - Securing the connection

The manometer should be firmly connected to the designated measuring point. A proper seal is necessary to avoid leaks that could affect measurement accuracy. - Reading the pressure value

Mechanical manometers display pressure on an analog dial, while digital models show the reading on an electronic screen.

When is it practical to use the bar pressure unit?

Using the bar unit is especially practical when components or system elements come from different manufacturers. Since bar is one of the most commonly used pressure units in Europe, the technical specifications of the following parts are almost always provided in bar:

- hoses

- valves

- pumps

- pressure-operated components

This simplifies system design and makes it easier to match components from various suppliers, reducing the risk of using incompatible parts.

Avoid incorrect hose selection caused by mixing pressure units!

Mixing pressure units is a common mistake, especially when working with components from different sources, countries, or manufacturers. A typical example is choosing the wrong hose, which can be dangerous.

A clear example of this is when a technical datasheet states that an industrial hose is rated for “max. 300 PSI.” However, the purchaser or installer mistakenly believes this means 300 bar and installs it into a system operating at 250 bar.

What happens in this case?

- The hose is overloaded.

- It may crack, leak, or completely rupture, leading to operational failure or even accidents.

- If the system contains oil, gas, or chemicals, the risk is even greater.

How to avoid this?

- Always check what unit the pressure is given in on each datasheet.

- It is recommended that all critical components (e.g., hoses, valves) use bar as the standard pressure unit when working within a metric system.